Ask any plumber over 40 about copper. They’ll recall long days with a torch in hand, sweating joints, checking for pinhole leaks, and charging the client for both time and materials. Solid, yes—but unforgiving. Overpriced. Vulnerable to acidic water.

Enter PEX. Flexible, freeze-resistant, simple to run through a maze of studs. And the true game changer? The fittings. Without plumbing PEX fittings, PEX would just be a fancy hose. The fittings are what allow plumbers to trust the pipe—crimped, clamped, pressed, even push-fit. Strong enough to handle decades, yet forgiving during installation.

What Nobody Tells You About PEX Fittings

Here’s something many glossy brochures won’t admit: not all fittings are equal. Brass fittings in hard-water regions can dezincify—tiny leaks appearing years later. Plastic fittings? Affordable, yes, but more fragile if exposed during construction. Stainless steel works beautifully, but you’ll rarely see it in a modest suburban home due to cost.

The insight here is that the choice isn’t just technical—it’s environmental and financial. A plumber worth their salt doesn’t just grab whatever’s cheapest. They’ll read the water chemistry report. They’ll think ahead ten or fifteen years. Because the wrong choice means callbacks, angry clients, and torn-out walls.

The Tools Behind the Work

People often imagine PEX systems as “snap and go.” That’s only half the story. You need tools—crimpers, expansion tools, or press systems—each matched to a fitting type. Choose wrong, and you’ll end up with a connection that weeps under pressure testing.

Here’s a real-world example: a contractor installs crimp rings without calibrating the tool. The system looks fine until it’s charged at 60 psi. A mist sprays out. Multiply that across ten joints hidden behind drywall. Suddenly that “easy” install turns into a nightmare. The fittings didn’t fail. The process did.

This is the part homeowners rarely see, but plumbers know: the fittings are only as good as the hand and tool applying them.

Shapes, Yes, But Strategy Too

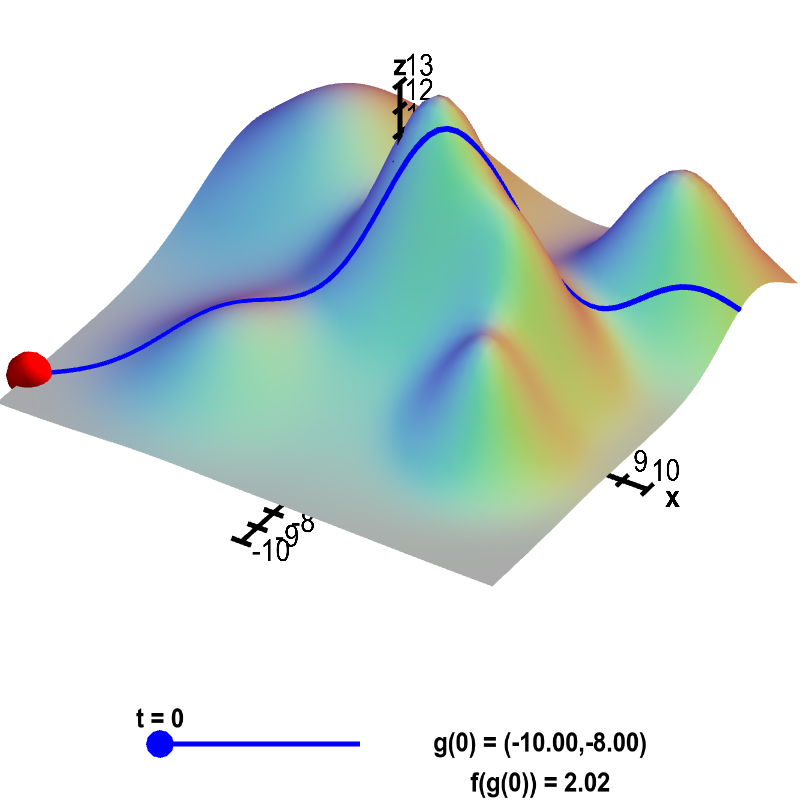

Elbows, tees, couplings, end caps. Sounds simple. But good design isn’t just about snapping them together like Lego. Too many fittings choke water pressure. Place an elbow where the line could have curved naturally, and you’ve added one more potential weak point.

Smart plumbers think like chess players—three moves ahead. They reduce fittings where they can, running long, smooth lines. When a fitting is needed, it’s placed strategically, not lazily. That’s the difference between a system that feels powerful at the tap and one that limps along with reduced flow.

Why PEX Wins for Plumbers and Clients

Let’s not pretend it’s perfect. PEX isn’t invincible. Mice can chew it. Sunlight degrades it. Some building codes still demand copper in specific applications. But when used properly, it beats old systems hands down.

Time savings are massive. Imagine re-plumbing a bathroom: copper might take two full days. With PEX, it’s half that. Less soldering, fewer fire hazards, no heavy lifting. Costs drop too—not just because material is cheaper, but because the labour bill shrinks.

In the thick of it, plumbing PEX fittings carry the weight. They lock the system together. They’re invisible once the walls close up, yet they’re the guardians of every drop that flows through the house.

Maintenance Isn’t Sexy—But It Matters

A plumbing system is judged not in the first week, but ten years later. Copper corrodes; steel rusts; fittings sweat under constant stress. PEX fittings? When installed correctly, they simply… disappear into the background. No clogs from mineral buildup. No sudden bursts in winter.

That reliability translates to peace of mind. Homeowners rarely think about it, but fewer service calls mean fewer bills. Appliances last longer because water pressure stays consistent. And let’s be honest—most people only notice plumbing when it fails. A well-installed PEX system is one they never think about.

The Overlooked Benefits

Noise reduction is one. Copper pipes bang—water hammer rattling through walls. PEX cushions the shock. Another? Environmental footprint. Manufacturing copper is energy-heavy; mining leaves scars. PEX uses less energy to produce and transport. That matters, even if it isn’t the first thing a client asks.

And here’s a practical bonus: remodels. Ever tried snaking rigid copper through an attic crawl space? A nightmare. PEX bends, flexes, feeds through holes without sweating every joint. It’s adaptable. That’s why it’s become the modern plumber’s ally.

Final Thoughts

Plumbing doesn’t grab headlines, but it quietly defines comfort in a home. The shift to PEX was more than convenience—it was necessity. Flexible, cost-effective, and resilient, it addressed the shortcomings of copper and steel.

But here’s the truth: none of it would work without the fittings. Those small pieces, unseen once the drywall is up, carry the whole system. By relying on plumbing PEX fittings, plumbers create systems that last, adapt, and perform. It’s not just about moving water; it’s about building trust in something you’ll never see, yet depend on every single day.